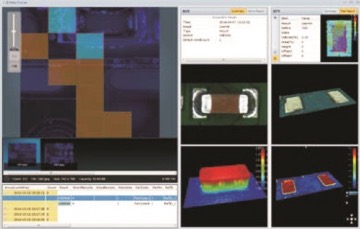

TROI-8800CI

Automatic optical coating inspection machine

Key Features

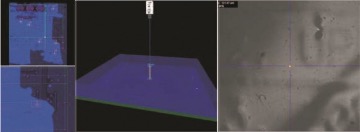

- 1. Automatic teaching and optimization

- By testing well-coated PCB samples, the system automatically identifies and sets reasonable parameters and uses them as standard values for actual production.

- 2. Reliable coating detection

- Programming is simple, testing is fast, and defects such as cracks, splashes, bubbles, and abnormal thickness (too thick, too thin) can be accurately detected.

- 3. Closed-loop feedback function

- Real-time monitoring & quality control solution, automatic matching system of detection results, providing intuitive monitoring of each production link.

- 4. Thickness measurement

- The thickness of the coating surface is measured using the principle of laser reflection.

- 5. Equipped with PCB flipping mechanism for double-sided detection

- The simple and fast PCB automatic flipping module can detect both sides of the substrate without removing the board.

Specifications

Device model | TROI-8800CI | TROI-8800CIL | |

camera pixels | 4005 |

| |

Lighting system | UV+RGB lighting |

| |

Test items | Cracks, bubbles, spatter, coating too thick/thin | ||

resolution | 10um | 15um | 18um |

Detection speed | 16.5cm2/sec | 38.4cm2/sec | 53.5cm2/sec |

FOV | 20.5×20.5mm | 30.7×30.7 mm | 36x36mm |

Substrate thickness | 0.4-7 mm | ||

Clear height of substrate | Top: 60mm Bottom: 60mm | ||

Detection area | 50 × 50 mm - 290 × 330 mm | 50 x 50 mm - 470 x 510 mm | |

Device power consumption | 220-240Vac, 1.5KW | 220-240Vac, 1.8KW | |

Equipment size | W900 × D1070 × H1545 mm | W1100 × D1220 × H1545 mm | |

equipment weight | 450kg | 500kg | |